In August 2018, raSmith acquired Matsen Ford Design Associates, a pioneer in cold-formed steel engineering since 1987. All Matsen Ford staff were retained by raSmith to join our existing cold-formed group in our Brookfield, Wisconsin office. raSmith has a niche expertise in cold-formed steel engineering (also referred to as light gauge steel engineering) projects and provides services to architects, builders, and general contractors on projects throughout the United States.

raSmith works on projects nationwide in conventional structural system design, cold-formed steel framing design, and finish systems design. raSmith now has one of the largest cold-formed steel engineering groups in the United States, complementing our overall structural engineering practice. Our diverse expertise and national experience enables us to continue expanding our geographic reach into new markets.

raSmith’s applications of cold-formed structural engineering include residential, sports, retail, educational, healthcare, mixed-use, corporate, industrial, senior living, and hospitality facilities. Our competitive pricing and proven track record for responsiveness are recognized by our clients nationwide.

Why Use raSmith as Your Cold-Formed Specialty Engineer?

raSmith's design expertise in cold-formed steel framing helps us provide the most efficient and economical design for your project.

- Lump-sum, competitive pricing.

- Preliminary member sizing to facilitate your bid estimates.

- Two to three week turnaround on most projects – please contact us for current lead times.

- Immediate response when you need answers during design and construction.

- Design solutions adjusted to accommodate your preferences on each project.

- On-call engineering support throughout design and construction until the project is complete.

- As an independent cold-formed engineer (versus a supplier specifying their own product) our services save you money.

- High-quality, detailed, and installer-friendly shop drawings.

- Proprietary connector requirements are minimized.

- Extensive experience with all building types.

- Licensed design professionals throughout the United States.

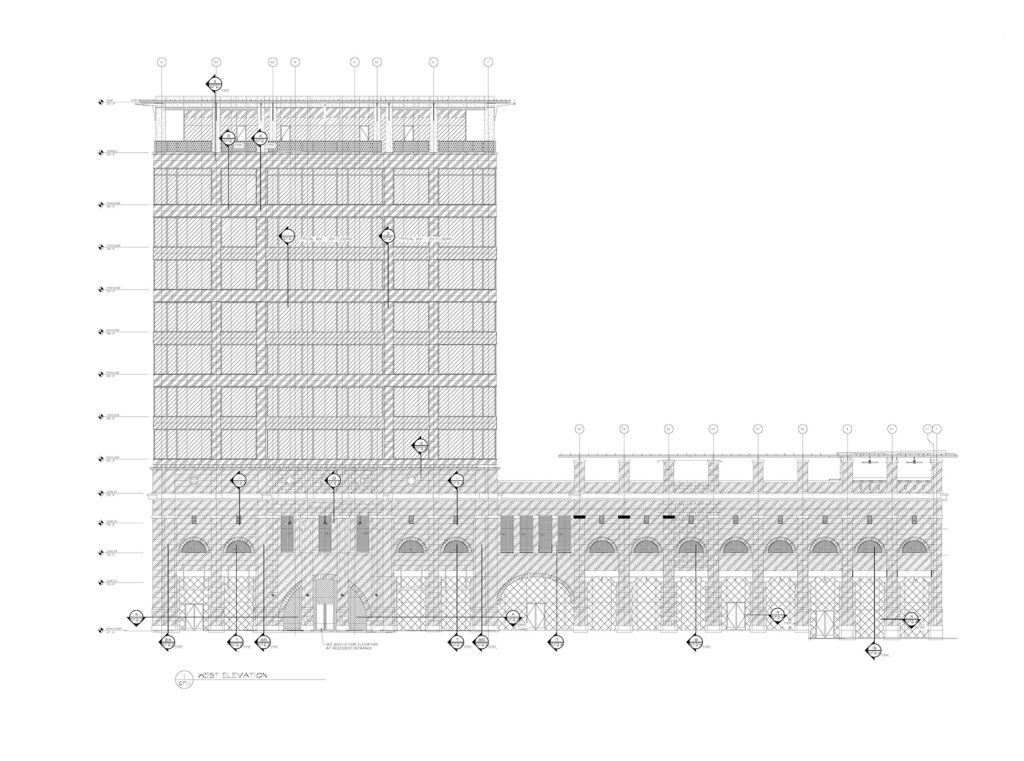

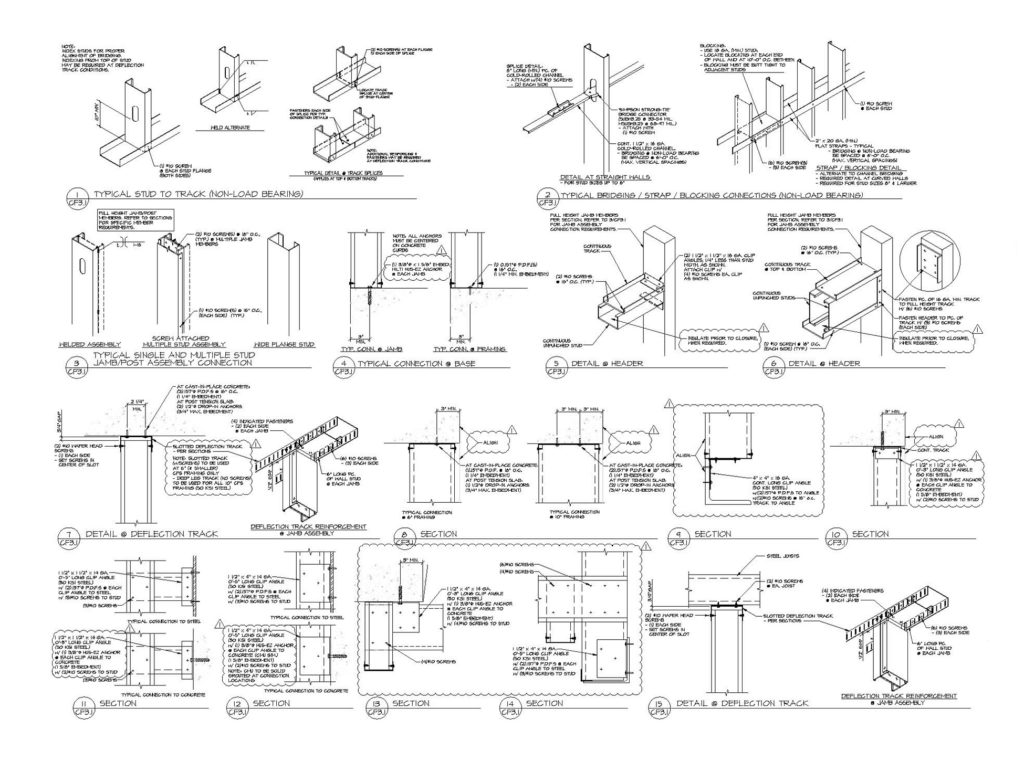

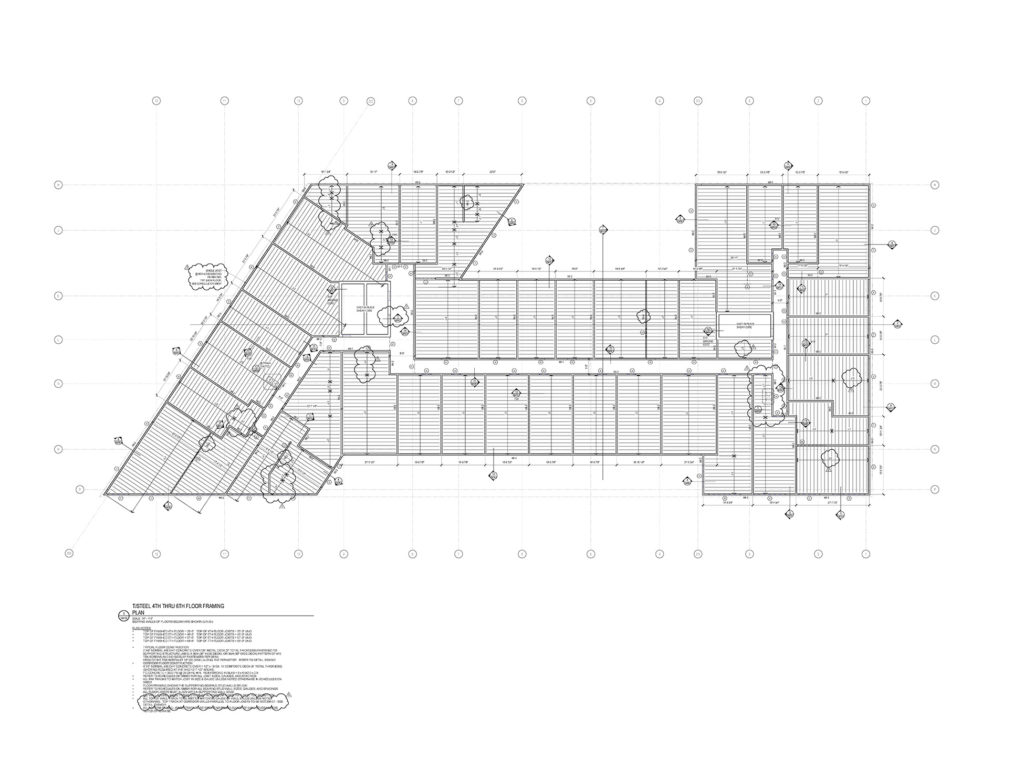

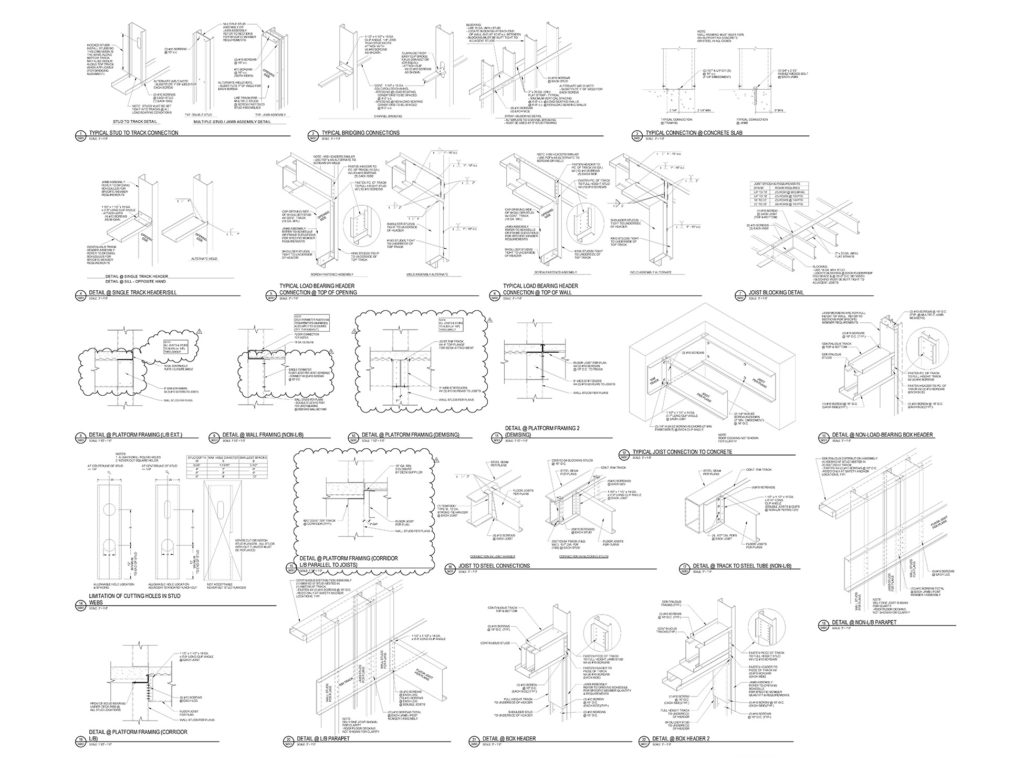

Sample cold-formed steel detail and shop drawings

Cold-Formed Steel Framing Benefits: Simple, Safe, And Strong

Cold-formed steel framing offers architects, builders, and specifiers a range of features and benefits that all contribute to shorter construction times, lower material costs, safer structures, and faster revenue generation. Steel is strong, safe, durable, versatile, and cost-effective. Steel has the exceptional environmental advantage of being highly recycled and infinitely recyclable. Steel is tough and does not rot, spawl, split, or absorb moisture, and is resistant to pests, unlike other building materials. From an aesthetic or architectural viewpoint, steel structures can easily deliver creative design options and excellent value. (Provided with permission from the Steel Framing Industry Association (SFIA).)

About Cold-Formed Steel Framing Systems

Lightweight, cold-formed steel members (typically “C” shapes) are assembled in various combinations to provide efficient, versatile, structurally sound framing systems for load-bearing walls, curtain walls, partitions, floors, and roofs. They have been used to provide the entire support for buildings up to 12 stories high, and are routinely used as secondary structural systems for heavy steel or concrete structural frames. In buildings of any type, shape, or size, they offer many opportunities for savings in materials costs, structural requirements, and construction time. They are easily insulated for energy conservation, provide an incombustible support for fire-rated construction, accommodate almost any exterior or interior facing, and are highly suited to pre-assembly into panels.

Prefabrication and panelization lead to improved quality control and construction speed. Framing contractors prefabricate wall and floor framing assemblies in advance in their shops or in fabrication facilities set up at or near the job site. Specifically designed assembly fixtures assure accurate dimensioning and alignment as well as place all operations at convenient working height for fast, efficient production.

As erection proceeds, the framing for a large floor or wall section is positioned, plumbed, and attached as a unit in a fraction of the time required for conventional stick-by-stick construction. Erection of steel on steel before floors are poured can avoid the delays in waiting for concrete pouring and curing.

Lightweight cold-formed steel framing can provide the entire structural support for midrise buildings of several stories, including designs with provisions to meet stringent high seismic loading requirements. This type of construction is also readily adaptable to curves, recesses, and other architectural treatments.

In curtain wall applications, sheathing and facing materials are frequently pre-applied to the framing assemblies. As these panels are installed, both framing and enclosure are accomplished in one operation. Properly framed door and window openings are included. Three-dimensional panels may be fabricated for column enclosures and other dramatic architectural features.

Steel Framing Industry Association Case Studies

raSmith has contributed to several case studies prepared by the Steel Framing Industry Association (SFIA). These case studies offer real-world examples of how cold-formed steel has been a necessary part of these successful projects.

- Wheaton Courthouse Square Case Study, Wheaton, IL

- City Green Case Study, Milwaukee, WI

- Convent Hill Case Study, Milwaukee, WI

Cold-Formed Steel Engineers Institute Design Excellence Awards

raSmith has received several Cold-Formed Steel Engineers Institute (CFSEI) Design Excellence Awards for projects throughout the United States.

- Office Building @Ovation, Newport, KY - 2023 (First place - commercial)

- Advocate Aurora Health Care - Lake Villa Clinic, Lake Villa, IL - 2023 (Third place - municipal/services)

- Starbucks (Staten Island), Staten Island, NY - 2023 (Second place - commercial)

- The Rosie, Chicago, IL - 2023 (Second place - residential/hospitality)

- Lexington Convention Center, Lexington, KY - 2022 (First place - municipal/services)

- SOS Children’s Village Roosevelt Community Center, Chicago, IL - 2021 (First place - residential/hospitality)

- Hub State Street, West Lafayette, IN - 2020 (First place - residential/hospitality)

- Stew Leonard’s, Paramus, NJ - 2020 (First place - commercial)

- The Rose Hotel, Chicago, IL - 2019 (First place - residential/hospitality)

- Dream Nashville Hotel, Nashville, TN - 2019 (Second place - residential/hospitality)

- Apple Store – Michigan Avenue, Chicago, IL - 2019 (Third place - commercial)

- 1600 West Loop South Ballroom Ceiling, Houston, TX - 2018 (First place - commercial)

- The Cade Museum for Creativity and Invention, Gainesville, FL - 2017 (First place - municipal)

Professional Association Involvement

raSmith’s cold-formed steel engineering group leaders Jeff Derra and Pat Hainault have been active in the Steel Framing Industry Association (SFIA) and Cold-Formed Steel Engineers Institute (CFSEI) for the better part of their careers. Pat Hainault currently serves on the CFSEI Executive Council.

Pat Hainault is a member of the American Iron and Steel Institute (AISI), Association of the Wall and Ceiling Industry (AWCI), and the American Society of Civil Engineers (ASCE).

Jeff Derra is a member of the American Institute of Steel Construction (AISC) and the Association of the Wall and Ceiling Industry (AWCI).

Cold-Formed Steel Services

Multi-story load bearing

Exterior curtain wall framing

Pre-fabricated wall panel design

Raised platform framing

Interior framing

Exterior façade renovations

Pre-finished panel design

Blast design